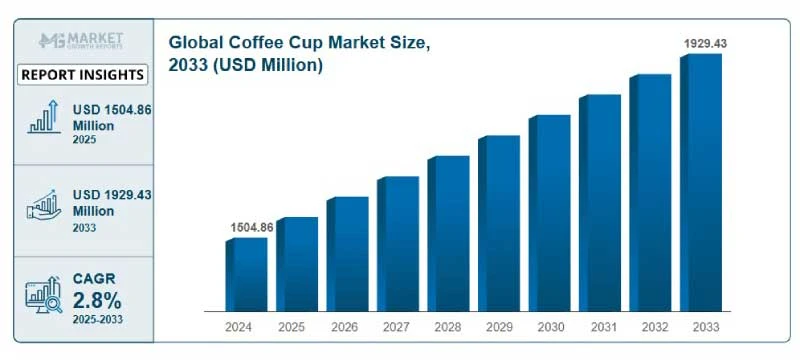

As the global paper cup market continues to expand, the 12oz size has firmly established itself as the leading “medium” option. According to MarketGrowthReports, the global coffee cup market reached $1.505 billion in 2024 and is projected to grow to $1.929 billion by 2033. The 12oz cup alone accounts for roughly 35% of total sales. A separate report by Lucintel also highlights the 9–12oz segment as the fastest-growing volume range, with 12oz emerging as the most in-demand subcategory.

The 12oz paper cup is popular and fits nearly every mainstream beverage, from coffee and milk tea to fast food combos and specialty drinks. But how do you find the right 12oz cup for your brand—and avoid common pitfalls in bulk purchasing?

As a paper cup manufacturer with years of export experience, GMZ created this guide to help you pick the best 12oz cup for your brand, covering everything from structure and materials to sourcing and supplier tips.

Why 12oz Is the Most Popular Cup Size?

Beyond market statistics, leading brands have already confirmed the 12oz cup’s dominance with their own product choices. Starbucks uses a 12oz cup as its “Tall” size (approximately 355ml), the most popular choice for hot drinks. Costa Coffee also adopts 12oz as the standard “small” cup across its stores globally, even developing matching eco-friendly lids and recycling programs around this size.

This shared consensus underscores 12oz’s status as the everyday standard in today’s made-to-order beverage market. So, why is it so popular?

1. Comfortable and Just-Right Volume

With a capacity of 355–360ml, it covers the standard portion for drinks like lattes, Americanos, milk tea, or hot chocolate. It’s not too small to leave customers unsatisfied, and not too large to create waste. Compared to the 8oz (a bit petite) and the 16oz (often considered oversized), 12oz is the psychologically “just right” medium.

2. Operational Compatibility Across the Board

The 12oz size is easy to standardize. Most universal lids, stirrers, and cup holders are already designed to fit it, so there’s no need for extra accessories or special inventory. This reduces complexity in stock management and helps chain stores maintain consistency across locations. Its moderate surface area also makes it ideal for branding—there’s enough room to display logos, promos, or designs clearly, without looking cluttered or wasting print space.

3. Better Customer Experience

With a comfortable weight and easy grip, the 12oz cup feels just right in hand, whether customers are grabbing it to-go or enjoying it on-site. That “everyday convenience” makes it more likely for people to come back and even share their drinks on social media, helping brands drive repeat purchases and word-of-mouth visibility.

How do you choose the right 12oz paper cup?

While 12oz is clearly a great size, not all 12oz cups are created equal. Choosing a cup isn’t just about picking the right volume—you also need to look at the materials, structure, coating, and other key details. In the following sections, we’ll break down five important factors to help you make a smart, informed decision.

1. Cup Material

A high-quality 12oz cup begins with food-grade virgin paperboard, featuring a smooth surface, strong stiffness, and no fluorescent additives. The stronger the paper, the better it holds its shape when exposed to heat or pressure, which is critical for hot drinks.

Paper weight also varies by cup structure. Single-wall cups typically use 180–230gsm paper, making them suitable for room-temperature or short-term hot beverages. In contrast, double-wall and ripple cups require heavier paper—often 350–400gsm or more—to provide added insulation and resist deformation.

2. Coating matters

A cup’s performance depends not only on the paper but also on its inner coating. The coating affects how well the cup resists leaks and heat, and whether it meets recycling standards and environmental regulations in different regions.

The three most common coatings on the market are polyethylene (PE), polylactic acid (PLA), and water-based coatings. The table below compares their materials, advantages, drawbacks, and suitable markets to help you make an informed choice.

| Coating Type | Material Source | Main Advantages | Limitations | Target Markets / Regulations |

| PE Coating | Petroleum-based (Polyethylene) | Low cost, mature production, strong leak resistance, high heat tolerance | Non-biodegradable, hard to recycle, restricted under EU SUPD and California laws | Suitable for most markets, but must be labeled and separated in EU, California |

| PLA Coating | Plant-based (Polylactic Acid) | Biodegradable, eco-compliant, aligned with green consumption trends | Higher cost, lower heat resistance, needs industrial composting to degrade | Preferred in regions with strict green policies (EU, California, Washington, etc.) |

| Water-based Coating | Non-plastic coating tech | Recyclable with paper waste, plastic-free, supports “Plastic-free” initiatives | Complex process, higher material standards, more expensive, limited market acceptance | Ideal for eco-conscious markets with plastic-free labeling or certifications |

Of course, there are also other coatings used in the market, such as PBS coatings, mechanical barrier finishes (greaseproof or no-liner types), and water-soluble bio-based films. We won’t go into detail here. Each coating type comes with its own pros, costs, and regulatory implications. When selecting the right one, it’s important to align with your target market’s environmental standards and the specific use case of your customers.

3. Cup Structure

The three most common structures for 12-oz paper cups are single-wall, double-wall, and ripple-wall. Each structure significantly affects insulation, grip comfort, and even your brand’s market positioning, especially for hot drinks.

- Single-wall cups are the most basic type, consisting of a single layer of paper with an internal coating. They’re low-cost, easy to stack, and suitable for short-term use, but they offer little heat protection and usually require a sleeve.

- Double-wall cups add an outer insulating layer, improving both heat retention and hand comfort. They’re popular with branded coffee shops and takeaway tea chains.

- Ripple cups take it a step further. Their outer layer is embossed with a textured ripple design, offering enhanced insulation, a non-slip grip, and a more premium visual feel. These are often used at events, in fast-food chains, or higher-end beverage settings to catch consumer attention.

4. Print Quality

Great printing isn’t just about good visuals—it’s a key part of brand communication. A well-designed, Instagrammable 12oz cup can become a walking ad, driving real traffic and customer loyalty. That’s why it’s important to consider print capabilities when sourcing: Can it support CMYK or Pantone? Are premium options like UV, embossing, or textured finishes available? How clear and color-accurate is the result? Reliable suppliers will also offer sample proofing and maintain stable production workflows to ensure your branding comes out exactly as intended, every time.

5. Lid Fit and Stackability

After picking the right cup material, coating, and print, many brands stumble on the final step—either the lids don’t fit properly and cause leaks, or the cups stick together and slow down service. These small issues are often overlooked but directly affect customer satisfaction and store efficiency. Even though 12oz is a common size, slight differences in rim diameter and rolled edge thickness can cause mismatches between cups and lids. Always test lid compatibility before placing large orders.

Stackability also matters—especially for ripple or double-wall cups. Poor design can lead to “stuck cups” that staff struggle to separate, hurting speed and flow during peak hours. Many baristas on Reddit have flagged this as a real problem—and one that’s easily preventable with good sourcing.

Beyond the Cup: Smart Sourcing Strategies for 12oz Paper Cups

Finding the right 12-oz paper cup is only half the equation—choosing the right supplier is just as critical. While price and product specifications matter, factors such as minimum order quantities (MOQs), packaging formats, compliance, and service quality often make the real difference, especially in large-volume or customized orders. A cheap quote may seem appealing upfront, but a weak supply chain can lead to delays, failed inspections, or missed sales opportunities.

• MOQ matters – Standard stock cups may require just 5,000–10,000 units. But if you’re ordering custom prints, eco-friendly coatings, or unique structures, MOQs can jump to 50,000 or more. Always confirm volume thresholds and pricing tiers upfront.

• Packaging flexibility – Most 12oz cups are packed in bulk cartons (e.g., 1,000 pieces per box) or palletized. Some suppliers also offer retail-ready options, such as branded boxes or inner sleeves, to facilitate storage and distribution.

• Avoid common pitfalls – Don’t underestimate the impact of poor coordination. Misaligned artwork, designs hidden by rim folds, missed shipping deadlines, or non-compliant coatings (like failing EU SUPD rules) can ruin an entire campaign. Double-check specs, timelines, and local regulations early.

• Understands export markets – Experience shipping to regions like the U.S. and EU is essential, especially with complex rules around food contact and sustainable packaging.

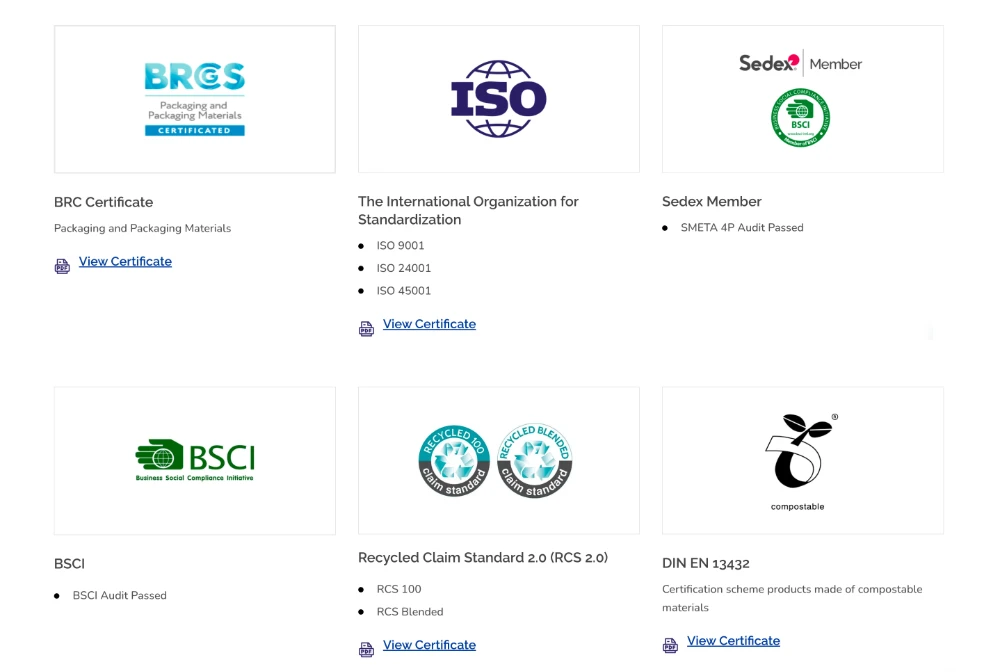

• Holds proper certifications – Look for suppliers that provide FDA, LFGB, BPI, or other compliance documentation, especially for coatings and biodegradable materials.

• Offers responsive support – Fast sampling, quick revisions, and proactive communication make a huge difference, especially when timelines are tight or you hit unexpected snags.

That’s why choosing the right partner matters—and why GMZ could be the supplier you’re looking for. As a China-based manufacturer specializing in paper cup production and export, we offer not only a wide range of structural designs and eco-friendly coatings, but also a comprehensive range of services. We also help brands manage the entire packaging process—from mold customization and compliant labeling to tailored packaging formats and smooth logistics coordination. If you’re exploring reliable options for your next 12oz paper cup order, we’d be happy to share our experience and insights.

Final Thoughts

In the world of disposable packaging, the 12oz paper cup stands out not just for its popularity but for its balance of function, comfort, and branding potential. From ergonomic sizing and insulation options to regulatory compliance and visual design, it’s a small product with big strategic value.

Whether you’re a coffee chain, distributor, or growing beverage brand, finding the right cup—and the right partner behind it—can make a real difference. If you’re planning your next packaging move, we welcome the opportunity to connect.